How to make large roofs with PV insurable? The engineering perspective

We turn roofs with PV from an unacceptable risk into an insurable roof system. Mineral fire protection designed to limit fire spread under PV arrays and support insurer acceptance, aligned with the FM Approvals approach and RoofNav conventions.

Why this matters for engineering review

PV systems can fail, even with high-quality components, monitoring and inspections. Electrical faults, connector issues and installation defects can lead to ignition events under the array. The underwriting question is therefore not whether ignition can be prevented in every case, but whether the roof system limits fire spread under the PV array and prevents flame penetration into combustible layers, reducing consequential loss and downtime.

Keep a local incident local.

FM reference and RoofNav context

Most insurers and risk engineers use FM Approvals as the benchmark and RoofNav as the reference framework for defined roof systems and documented performance. In practice, engineering review often hinges on the specific RoofNav assembly, including the assembly number, the full build-up definition and the uplift rating.

Direct access to FM documentation

Risk engineers often need to verify the FM status quickly. Provide direct access to technical documentation and RoofNav assembly references for the selected build-up.

Evidence, in one glance

- Defined roof build-ups and PV configurations, structured for engineering review in line with RoofNav conventions.

- Evidence packs for underwriting files, including FM Approval documentation and PV-related fire test documentation where applicable.

- Workmanship control requirements and copy-ready wording for risk reports.

Independent test evidence beyond FM

FM Approvals is often the primary benchmark in international underwriting. In Europe, insurers and risk engineers may also reference local external fire performance classifications, including Broof(t1,2,3 and 4) under EN 13501-5.

Where EN 13501-5 documentation is available for the selected build-up, include it in the evidence pack alongside FM Approval documentation to support non-FM underwriting pathways while keeping the system review defensible.

Three routes to a functionally non-combustible roof system with PV

For underwriting and risk engineering, there are three practical situations for roofs with PV. The objective is always the same. Make the roof system functionally non-combustible beneath PV arrays to limit fire spread and prevent flame penetration into combustible layers, supporting insurer acceptance and reducing consequential loss.

Route 1. The roof system is already functionally non-combustible

PV can be permitted when the roof build-up is defined, documented and verified and when workmanship control is in place.

Route 2. Add an FM 4484 Approved mineral roof-PV coating where applicable

For retrofit projects where the existing roof assembly remains in place and a coating solution is suitable, an FM 4484 Approved mineral roof-PV coating can be used to create a functionally non-combustible barrier layer beneath the PV array.

Important limitations:

- On roofs with composite or insulated metal roof panels, a coating route is not applicable.

- the existing roof has to be water tight and not older than max 20 years, during application the seams in the roofing might be damaged and create leaks.

- limited application period; only during dry and not humid weather.

- ambient outside temperature more than 5 °C for 24 hours during application.

Route 3. Add an FM 4470 or FM 4478 Approved mineral cover board as part of the roof system

For new build and refurbishment, or when a coating is not suitable or not allowed, a mineral cover board can be integrated in the new roof build-up to create a functionally non-combustible barrier layer beneath PV arrays.

Preferred route

Where a roof build-up can be defined and detailed, the cover board approach is the preferred risk position because it is a robust, system-based method to control fire spread and protect underlying layers, with clear workmanship control and documentation aligned with RoofNav-style system review.

Quick selection guide

Preferred. Functionally non-combustible roof system route using a mineral cover board, FM 4470 Approved and FM 4478 Approved.

Use this category for defined roof build-ups in new build and refurbishment, for projects where roof membrane service life must match PV service life and whenever a robust, defensible system approach is required. This category can be implemented using AllShield mineral cover board solutions.

Alternative. Functionally non-combustible roof system route using a mineral roof-PV coating, FM 4484 Approved.

Use this category only where the existing roof assembly remains in place and a coating solution is applicable, subject to substrate condition, membrane type and detailing. This category can be implemented using an AllShield mineral roof-PV coating solution.

RoofNav assembly references

For FM insured projects, “FM Approved” is not enough on its own. Risk engineers typically require the defined roof assembly in RoofNav, including the assembly number and the uplift rating, alongside the full build-up definition.

Note:

Provide the RoofNav assembly number for each build-up variant and the attachment method, including edge and corner zone requirements. Provide the uplift rating as listed in RoofNav for that assembly, for example 1-90 or 1-120 depending on the complete system.

Why a lightweight mineral cover board

A common engineering question is why a project should specify a mineral cover board instead of adding thickness or weight with traditional solutions such as extra mineral wool, ballast or additional heavy layers.

A lightweight mineral cover board can provide a robust barrier function with limited impact on structural reserve capacity. This helps when PV is added to existing roofs where the structure, insulation and membrane system have limited tolerance for additional permanent load.

|

Engineer's question |

Typical default approach |

Lightweight mineral route |

|

How to limit fire spread |

Add thickness or heavier layers |

Add a mineral barrier layer in a defined build-up |

|

Structural reserve |

Added permanent load increases risk |

Lower weight reduces structural impact |

|

Point loads |

Accept risk or change mounting |

Cover board helps distribute loads |

|

Service life |

Keep membrane, add PV |

Align membrane life with PV life |

Evidence overview by application

|

Rf build-up or scenario |

Preferred route |

Alternative route |

Notes for engineering review |

|

New build roof with PV |

Cover board route |

Not applicable |

Define the build-up, RoofNav assembly reference, uplift rating and workmanship control. |

|

Refurbishment roof with PV |

Cover board route |

Sometimes coating |

Use cover board when service life alignment is needed. Provide RoofNav reference and uplift rating. |

|

Existing roof remains, PV added |

Cover board route if membrane life is limited |

Coating route if applicable |

Coating only if watertight, compatible and detailed. Provide FM 4484 documentation. |

|

Roof with point load limitations |

Cover board route |

Not applicable |

Cover board distributes loads and protects layers. |

|

Composite or insulated metal roof panels |

Cover board route |

Not applicable |

Coating route not applicable. |

Wind uplift and mechanical loads with PV

PV arrays change wind loading on roof systems. For a defensible engineering review, wind uplift and mechanical performance must be assessed at roof assembly level, including deck, insulation, cover board, membrane attachment and PV mounting method.

Where FM is used as the reference framework, present documentation in a way that maps to FM assembly thinking and RoofNav conventions. Provide the roof build-up definition, attachment method and the applicable FM documentation for the selected system. Confirm that project-specific detailing and workmanship control is in place, particularly in edge and corner zones where uplift demand is highest.

Checklist for engineering review:

- Confirm PV mounting method and load paths into the roof assembly.

- Confirm attachment method for the membrane and cover board.

- Confirm edge and corner zone detailing and fastening requirements.

- Include workmanship control checkpoints for transitions, penetrations and roof edges.

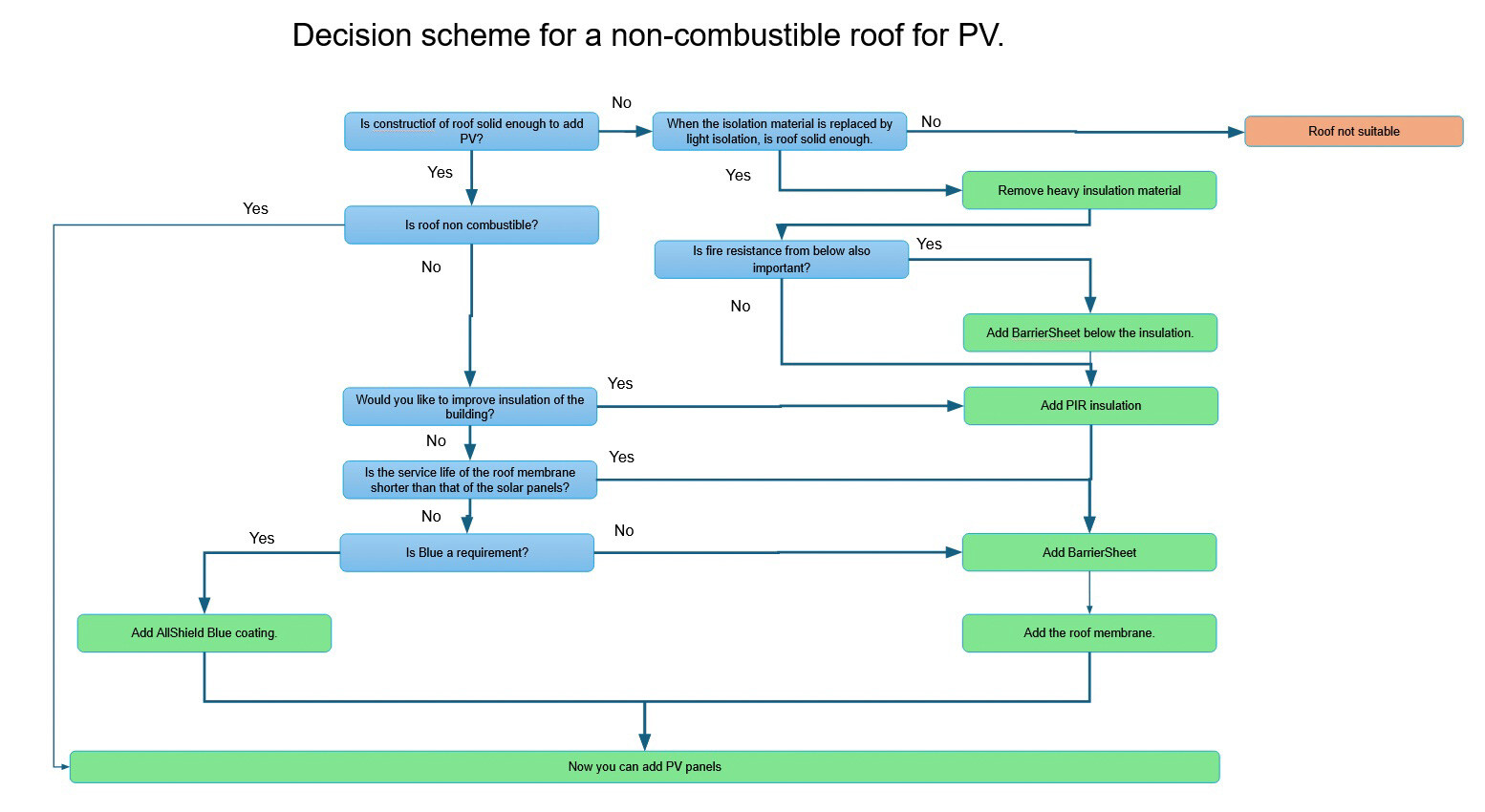

Decision tree

A practical tool for roof owners, insurers and risk engineers to select a defensible route to a functionally non-combustible roof system for PV. 🔍 Click on the image to enlarge.

Copy-ready wording for risk reports

- “PV systems can fail, even with inspections and monitoring. Because ignition cannot be eliminated with certainty, the risk control objective is to limit fire spread under the PV array and prevent flame penetration into combustible roof layers, reducing consequential loss and downtime.”

- “The preferred risk position is a functionally non-combustible roof system achieved by integrating a mineral cover board in a defined roof build-up beneath PV arrays, aligned with FM Approvals and RoofNav style system review.”

- “Where retrofit is required and the existing roof assembly remains in place, an FM 4484 Approved mineral roof-PV coating may be used where applicable, subject to substrate condition, membrane type and detailing.”

- “Final acceptance is project-specific and depends on defined build-up, detailing and workmanship control, especially at edges, penetrations and transitions.”

Next step go to download page to download relevant documents.

Our roof fire 🔥 protection solutions

Fire safety is the goal, insurability is the result

Flat roofs – especially those with solar panels – face an increasing fire risk. Even the best fire-retardant membranes offer limited protection against flying sparks or thermal ignition beneath PV panels. That’s why AllShield developed two non-combustible fire protection systems, each tailored to a specific application.